High Alumina Premelting Refining Slag Calcium Aluminate Ladle Refining Slag for Steelmaking

Overview Package Size 150.00cm * 150.00cm * 150.00cm Package Gross Weight 1000.000kg High alumina premelting refining sl

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | refining slag |

| Shape | Powder |

| Material | Casting Mold Powder |

| Cao Content (%) | More Than 35% |

| Al2O3 Content (%) | More Than 35% |

| Features | High Activity, Fast Slagging Speed |

| C Content (%) | More Than 35% |

| Purpose | Used for Protective Casting of Steelmaking Mould |

| Application | Industrial Furnaces |

| Maximum Service Temperature | 1400-1650 |

| Function | Functional Refractories |

| Certificate | ISO9001 |

| Product Name | Refining Slag for Steel Industry |

| Transport Package | Bag |

| Specification | 25kg/bag, 50kg/bag |

| Trademark | RSNC |

| Origin | China |

| HS Code | 3816000000 |

| Production Capacity | 50000 Tons/Year |

Packaging & Delivery

Package Size 150.00cm * 150.00cm * 150.00cm Package Gross Weight 1000.000kgProduct Description

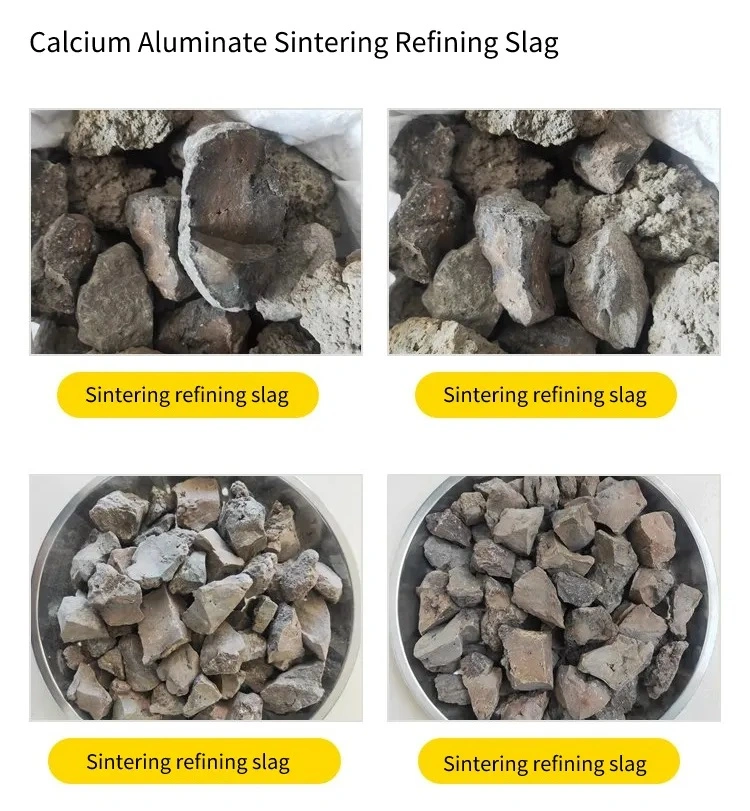

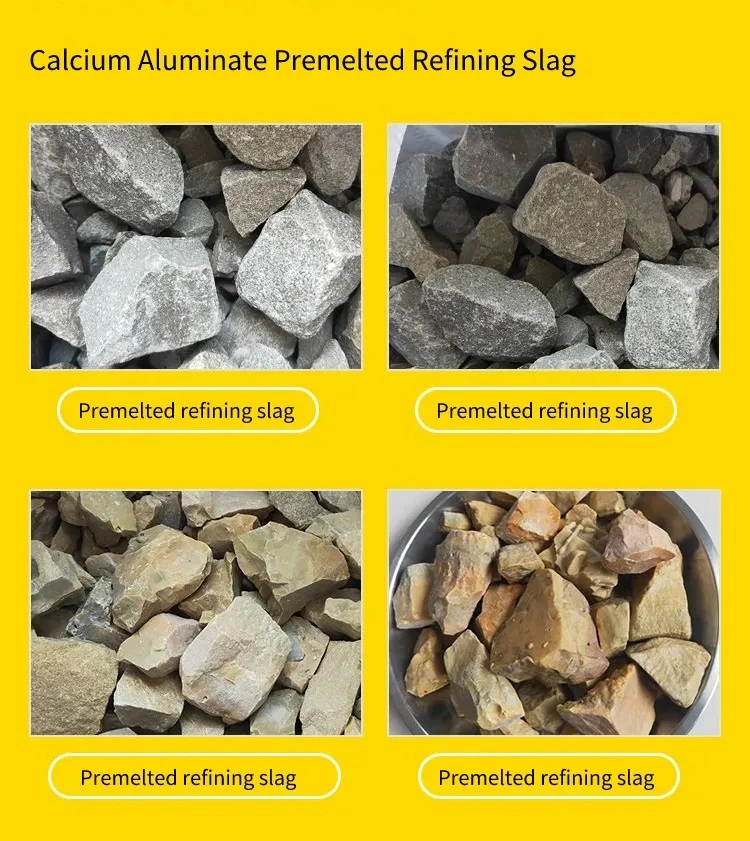

High alumina premelting refining slag calcium aluminate ladle refining slag for steelmakingProduct Description

Refining Slag Features

Refining slag is a new generation of steelmaking auxiliary products developed by our company to meet the requirements of low-sulfur and low-nitrogen steel. This is made from a variety of materials by special technology to 12CaO, 7Al203-based substances, the content of more than 90%, the activity coefficient of more than 70. The product has the advantages of fast melting, low gas content, high activity, fast slagging speed, early appearance of white slag, good fluidity after melting, adsorbing most of the deoxidization and desulphurization products in molten steel, shortening refining time and reducing steelmaking cost. Thus, the purpose of reducing the content of harmful impurities in molten steel and purifying the composition of molten steel is achieved.Usage and dosage.

1. Join with the steel flow or in the refining furnace when tapping.2. The consumption of refining slag per ton of steel is 5-8kg

Packaging, storage and transportation.

1. Packing material and unit weight can be customized according to user's needs.2. Waterproof, rain-proof and moisture-proof measures should be taken during storage and transportation.Specification

Physical And Chemical Indicators Of Refining Slag

| physical property | water content | 100 mesh size | Unit weight (g/cm3) | melting point | Melting rate | Adaptation conditions |

| Bz1 | <0.5 | >90 | <0.9 | 110-1150 | 35 | <1 ton ingot type |

| Bz1 | <0.5 | >85 | <0.9 | 1150-1200 | 35 | 3-8 ton ingot type |

| Gx3 | <0.5 | >90 | <0.9 | 1130-1170 | 35 | 1-3 ton ingot type |

| SBz | <0.5 | >90 | <0.9 | 1110-1160 | 25 | For stainless steel |

| chemical composition | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Fixed carbon | R2O | R |

| 35-45 | 35 | 8-13 | <5 | - | <4 | 14 | 1 | 0.3 |

| 30-40 | 30 | <10 | <5 | - | <3 | 18 | - | 0.4 |

| 35-42 | 35 | 7-11 | <5 | - | <4 | 15 | - | 0.45 |

| 35-45 | 35 | 15-19 | <5 | - | <5 | 1 | 4 | 0.45 |

Refining Slag Application

Refining Slag main function is to deoxidize, desulfurize and slag-making inthe steel smelting process to enhance the quality of steel

Packaging :1. Packing material and unit weight can be customized according to user's needs.2. Waterproof, rain-proof and moisture-proof measures should be taken during storage and transportation.

Zhengzhou Rongsheng Refractory Material CO., LTD.Established in the early nineties of twenty century, with continuous innovation and development, now it is a comprehensive enterprise in refractory materials industry, covering metallurgy, building materials, electric power, chemical industry etc.We have own workshop , advanced production line , experienced workman and stricted check out flow .So choosing us is the right choice for you.If you are interested in our Low cement refractory castables or if you have any question, pls feel free to contact us at any time. We will reply as soon as possible.

Customer Visiting

Now we have established cooperation relationship with many science and research unit and our products have been sold to Japan, Indonesia, Russia,Kazakhstan and Vietnam etc.We provide service that bring 100% of our customers back.So many customers make business with Rongsheng Refractory.We have no gap in communication.The customers all keep long-term relationships with us.Send inquiry here to get more information !!!